Safety Clamp Repair & Maintenance Kits

Bird's Clamps offers safety clamp repair, replacement and maintenance kits, which are readily available and easy to order to save you the trouble of ordering individual replacement parts should the need arise.

Safety Clamp Maintenance Tips

To function safely and have a long product life, clamp components should be disassembled and cleaned per the instructions contained within the clamps operational manual and logbook.

Each component should be thoroughly inspected for cracks, distortion and wear, and any component showing signs of these defects should be replaced. Upon reassembly, moving parts should be lubricated. See Safety & Inspection for detailed inspection notes.

Clamps should never be ground, welded or modified in any way and only maintenance kits and replacement parts from the manufacturer should be used with any kind of clamp.

Bird's Clamps offers maintenance and parts kits and demonstration videos for our clamp products.

| Kit No. | Description |

|---|---|

| KSC-1 | Cam and Seat Assembly; no. SC-42 (2), SC-35, SC-44, SC-46 |

| KSC-2 | Locking Assembly; No. SC-61, SC-65 |

| KSC-3 | Cam Yoke Assembly; No. SC-80(2) |

| KSC-4 | Pins; No. SC-37, SC-54 |

| KSC-5 | Cam Yoke Assembly - HC or VLC; Part No. SC85(2) ONLY, Prior to 1986 |

| SC-10 | Lifting Shackle |

| SC-16 | Body Bolts |

Obtaining a repair and maintenance kit has many advantages, as all of the working parts of Bird's Clamps are replaceable. Through constant use, some components of a clamp may experience wear and tear over time. Using a maintenance kit produced by the manufacturer saves you the cost of ordering individual components, reduces the inventory hassle of keeping track of individual parts, simplifies maintenance and will result in a longer product life through more thorough and proper maintenance.

To reduce the necessity of replacing parts, all workers should be trained in using Bird's Clamps safely. Clamps should be frequently inspected to ensure they are in optimal working condition. The specifications of each clamp should also be suited to the requirements of each use.

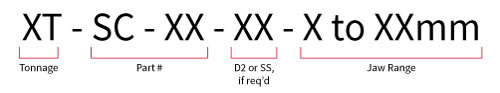

When ordering parts, please specify tonnage rating and jaw range of the intended clamp, as shown below.

Contact Bird's Safety Clamps today for more information.